Safer De-Icing and Ice Control Methods on a Construction Site

Winter on a construction site is never subtle. Snow shows up uninvited. Ice overstays its welcome. And suddenly every walkway is a potential workers’ comp claim waiting to happen.

This project focused on implementing safer ice control methods that kept workers upright, protected new concrete, and avoided the “just dump more salt on it” approach that causes problems later.

The Challenge

The site included newly poured concrete slabs, temporary access routes, stairways, and high-traffic entry points. Traditional chemical de-icers were not an option for much of the winter season.

The goal was simple (but not easy):

- Reduce slip-and-fall risk

- Protect concrete during its first winter

- Maintain safe access without creating new hazards

In other words: fewer slips, fewer repairs, and fewer awkward incident reports.

The Ice Control Strategy

CrossSafety worked with the project team to implement layered, practical ice control methods that focused on prevention first — chemicals last.

Mechanical Removal: The First Line of Defence

Manual shoveling, scraping, and rubber-blade equipment were used as the primary method of snow and ice control.

This approach:

- Eliminated chemical exposure

- Prevented surface damage to new concrete

- Worked best for fresh slabs still in their first winter

It’s not glamorous, but it works. Sometimes the safest solution really is a shovel.

Heated Mats and Temporary Insulation

Electric and hydronic heated mats were installed at:

- Entrances

- Stair landings

- Ramps

- Hoist access points

These systems provided continuous ice prevention without chemicals and were especially effective in high-traffic areas where ice tends to return five minutes after you clear it.

Bonus: fewer emergency call-outs when temperatures dropped overnight.

Anti-Slip Mats and Temporary Stair Treads

Some areas are just stubborn. For stairs, scaffolding platforms, and thresholds where ice build-up was hard to fully eliminate, non-slip walking surfaces were installed.

These added traction where it mattered most and reduced slip risk without relying on chemical treatments.

When Chemicals Were Used (Carefully)

Chemical de-icers were treated as a last resort and used only where:

- Concrete had fully cured

- Physical controls alone weren’t enough

- Access was critical

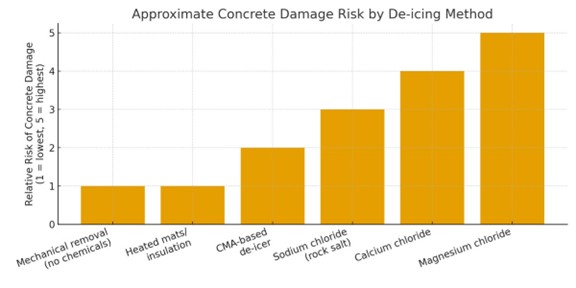

Here’s how different de-icing options stacked up.

Comparison of De-Icing and Ice Control Methods

| Method | Typical Use on Site | Risk to Concrete (1–5) |

|---|---|---|

| Mechanical removal | Primary snow and ice removal | 1 – Lowest |

| Heated mats / insulation | Entrances, ramps, stairs | 1 – Lowest |

| Anti-slip mats / treads | Stairs, platforms, thresholds | 1 – Lowest |

| CMA-based de-icer | Cured concrete access points | 2 – Low |

| Sodium chloride (rock salt) | Hardened exterior slabs | 3 – Moderate |

| Calcium chloride | Generally not recommended | 4 – High |

| Magnesium chloride | Avoid entirely | 5 – Very high |

Not all ice control methods are created equal. Some solve today’s problem by creating next spring’s repair bill.

The Outcome

By prioritizing mechanical removal, heated systems, and non-slip surfaces, the site maintained safe access throughout winter without compromising concrete durability.

Chemical de-icers were used sparingly, intentionally, and only when conditions truly demanded it. Sand was limited to short-term traction support and cleaned up promptly to avoid refreezing and drainage issues.

The result:

- Fewer slip hazards

- Less surface damage

- A calmer winter for everyone involved

The Takeaway

Effective ice control methods on construction sites aren’t about using more products — they’re about using the right controls in the right order.

Start with physical solutions. Add engineering controls where needed. Save chemicals for last. Your concrete (and your incident log) will thank you.

If winter safety planning feels like a guessing game, CrossSafety helps take the guesswork out — before the temperature drops.

Ready to Make Winter Safer on Your Site?

Snow and ice don’t have to turn into incident reports, concrete repairs, or last-minute panic decisions. The right plan — and the right controls — make all the difference.

CrossSafety supports construction projects with practical, on-site safety solutions that address real-world hazards like winter access, slip prevention, and site-wide risk management.

From seasonal hazard planning to hands-on safety support, we help teams stay compliant, protected, and moving — even when conditions aren’t ideal.

Latest News & Insights

Focus & Insights

What Are Health Safety Services and Which Ones Do You Actually Need?

Focus & Insights

What Does It Mean to Work in Safety – and How Do You Prove It?

Focus & Insights

Workplace Safety: What it Really Means and What a Practical System Includes