Confined Space Project – Underground Storm Water Retention Tank Removal

At 60 feet below grade, there is no margin for error. Here’s what happened on our recent confined space project in Vaughan, Ontario.

Client: Zencorp Mechanical

Location: Vaughan, Ontario

Sector: Mechanical / Infrastructure

Services Provided: Confined Space Planning, Atmospheric Testing, Ventilation, Attendant & Rescue Standby, Supervision

The Challenge

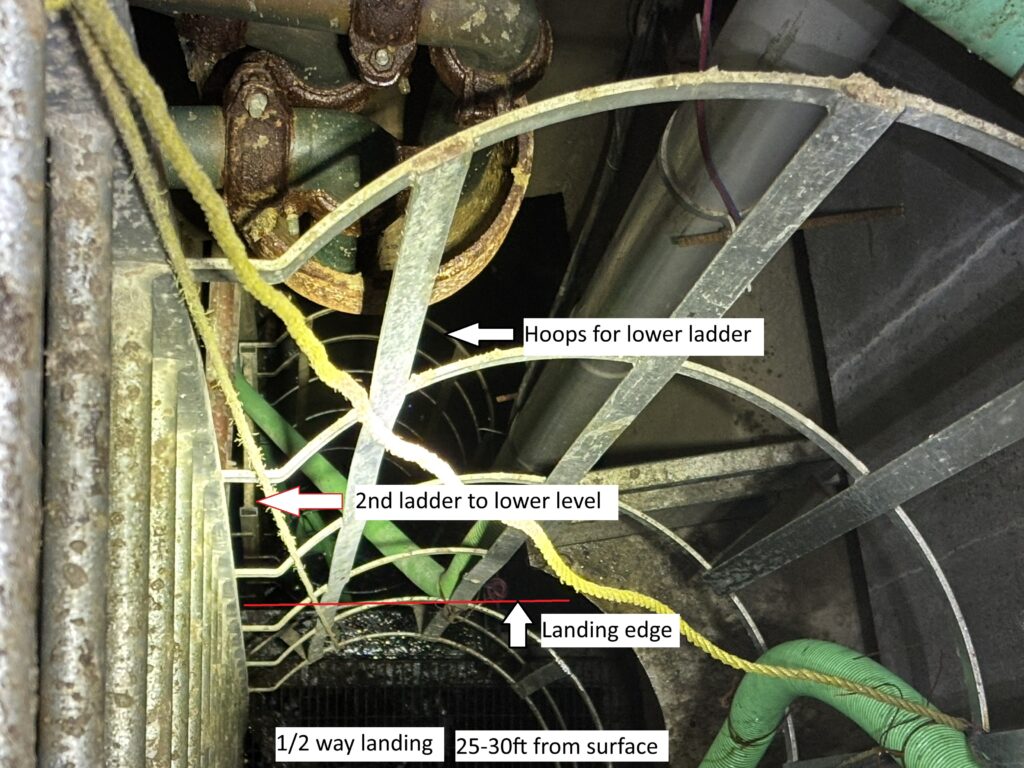

Zencorp Mechanical was required to enter a deep underground storm water retention tank at a condominium complex in Vaughan to remove three non-functioning pumps. The space extended approximately 60 feet below grade and was accessed through surface manholes connected to a vertical ladder system.

The work involved:

- Vertical entry and exit

- Limited natural airflow

- Mechanical equipment removal

- Multiple access points leading into the same confined space

Given the depth, configuration, and unknown internal conditions, the project presented significant confined space risks that required specialized planning and controls.

Why This Project Was High-Risk

Stormwater retention tanks are particularly hazardous confined spaces because atmospheric conditions can change without warning. In this case, the hazards were not visible from the surface.

Key risk factors included:

- Extreme vertical depth

- Ladder access with a mid-level landing approximately 25–30 feet below grade

- Potential for oxygen-deficient or contaminated atmospheres

- Limited rescue access in the event of an emergency

Without proper testing, ventilation, and rescue preparedness, entry into this space could have resulted in serious injury or fatality.

Our Role

CrossSafety was engaged to plan, implement, and oversee the confined space entry to protect Zencorp Mechanical’s workers and ensure the task could be completed safely.

Our scope included:

- Development of a site-specific Confined Space Entry Plan

- Pre-entry and continuous atmospheric testing

- Installation and operation of forced-air ventilation

- Confined space attendant services

- Rescue standby with dedicated equipment and trained personnel

- On-site supervision and coordination with the mechanical crew

The Turning Point: Hazard Identified

During atmospheric testing before entry, CrossSafety identified an oxygen-deficient atmosphere approximately six feet from the bottom of the tank.

This condition was not apparent from the surface.

Had workers entered the confined space without testing:

- Oxygen levels would have been unsafe

- The risk of collapse or loss of consciousness would have been high

- Rescue would have been extremely difficult given the depth

Instead, entry was stopped, and the space was ventilated until atmospheric conditions were confirmed safe.

This step alone likely prevented serious injury or worse.

Execution & Supervision

Once safe conditions were established, CrossSafety escorted Zencorp Mechanical’s workers into the confined space under continuous monitoring and supervision.

Inside the tank:

- Pump removal work was completed as planned

- Air quality was continuously monitored

- Ventilation remained in operation

- Attendants and rescue personnel remained on standby throughout

The Outcome

- Unsafe atmospheric conditions were identified before entry

- The confined space was ventilated to safe levels

- Three pumps were successfully removed

- No injuries or incidents occurred

- Work was completed efficiently and safely

Why This Matters

Confined space hazards are often invisible until properly assessed. This project highlights the importance of:

- Thorough pre-entry testing

- Site-specific planning

- Proper ventilation

- Trained attendants and rescue readiness

At 60 feet below grade, there is no margin for error. Proper confined space management is not about slowing work down — it’s about ensuring everyone goes home safely.

Confined Space Support You Can Rely On

CrossSafety supports mechanical contractors, general contractors, property managers, and developers with:

- Confined Space Entry Planning

- Attendant & Rescue Standby Services

- Atmospheric Monitoring & Ventilation

- High-risk underground and vertical entries

If your project involves confined spaces, early planning can make all the difference.

👉 Talk to a Confined Space Expert

.

Latest News & Insights

Focus & Insights

Workplace Infection Prevention for Healthcare Construction & Maintenance

Focus & Insights

Canadian PPE Changes in Construction: What’s New and What to Do Next

Focus & Insights

Ontario’s “As of Right” Labour Mobility Rules Are Here. Your OHS Due Diligence Isn’t Going Anywhere.