Confined Space Services – The Coxwell Bypass Tunnel

Confined-space services include planning, ventilation, entry support and standby rescue — completed safely on time and on budget.

Overview

In October 2025, CrossSafety provided comprehensive confined-space entry and rescue support to Black & Veatch for inspection work inside the City of Toronto’s 10.5 km Coxwell Bypass Tunnel.

Our client needed to descend to the base of a 51.6-metre-deep access shaft then proceed half-a-kilometer upstream through a curved section of the 6-metre-diameter sanitary tunnel to inspect segments following drilling operations within the tunnel’s proximity envelope.

With complex physical, atmospheric, and communication challenges, the work demanded precision planning, innovative ventilation and lighting, and fully integrated access and rescue capability.

CrossSafety’s newly established Confined Space Support Team led the effort, managing all phases of pre-planning, hazard assessment, equipment deployment, and live confined-space supervision.

The Challenge

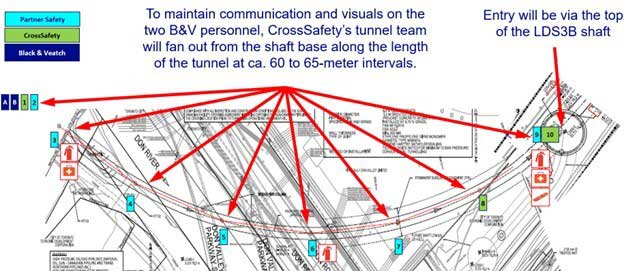

The operation presented unique confined-space risks: challenging access and egress, atmospheric uncertainty in the far reaches of the space, communication limitations due to the tunnel’s curvature and depth, and cold and rainy conditions on the dates of operations.

Our Approach

CrossSafety developed a comprehensive confined-space hazard control and rescue plan, integrating engineering controls, PPE, detailed task protocols, and specialized personnel and equipment.

- Drone Survey: We opened and drone surveyed the shaft days before entry to assess liquid levels at the base and the condition of staircases and platforms.

- Pre-Entry Hazard Assessment, Planning, and Visual Protocol Charts: Well in advance of entry a comprehensive hazard assessment and entry plan was formulated, supported by a slide deck showing step-by-step operations over the project cycle.

- Safety Briefings: Our client’s personnel received SCBA and escape-breather training, and a redundant communication protocol using radio, voice, horn, lamp, and hand signals.

- Ventilation Setup: Two 48-inch axial fans delivering 50,000 cfm were set up the day before entry to positively pressurize the shaft and connecting tunnels, producing 10 air changes per hour in the shaft. Tents were installed over the fans and ventilation shafts to prevent rain being sucked into the shaft.

Lighting: After ensuring safe atmospheric conditions in the upper portion of the shaft we installed 110,000 lumens of lighting on the upper half of the 12 storey staircase – creating daylight conditions in what started as a pitch-black work setting.

- Atmospheric Assessment: Pre-entry atmospheric testing was performed and all entry personnel were equipped with personal monitors. Thanks to the ventilation strategy air parameters in the shaft and tunnel were the same as at surface.

- Supervised Entry: Multi-level team deployment including rescuers, monitors, and client inspectors by a combination of crane basket and staircase — all equipped, kitted, and monitored to exact specifications.

- Emergency Response Readiness: Dedicated rescue systems and a full response plan in place throughout the operation.

The Results

✅ Zero incidents or injuries

✅ Inspection completed safely and on schedule

✅ Full compliance with regulatory requirements

✅ Client commendation for planning precision and field execution

This operation enabled Black & Veatch to complete critical inspection milestones on schedule, demonstrating CrossSafety’s ability to deliver end-to-end confined-space management with confidence and control.

Partner with CrossSafety for complex confined-space operations.

From engineering to rescue, our team ensures every entry is safe, compliant, and controlled.

Latest News & Insights

Focus & Insights

Workplace Infection Prevention for Healthcare Construction & Maintenance

Focus & Insights

Canadian PPE Changes in Construction: What’s New and What to Do Next

Focus & Insights

Ontario’s “As of Right” Labour Mobility Rules Are Here. Your OHS Due Diligence Isn’t Going Anywhere.